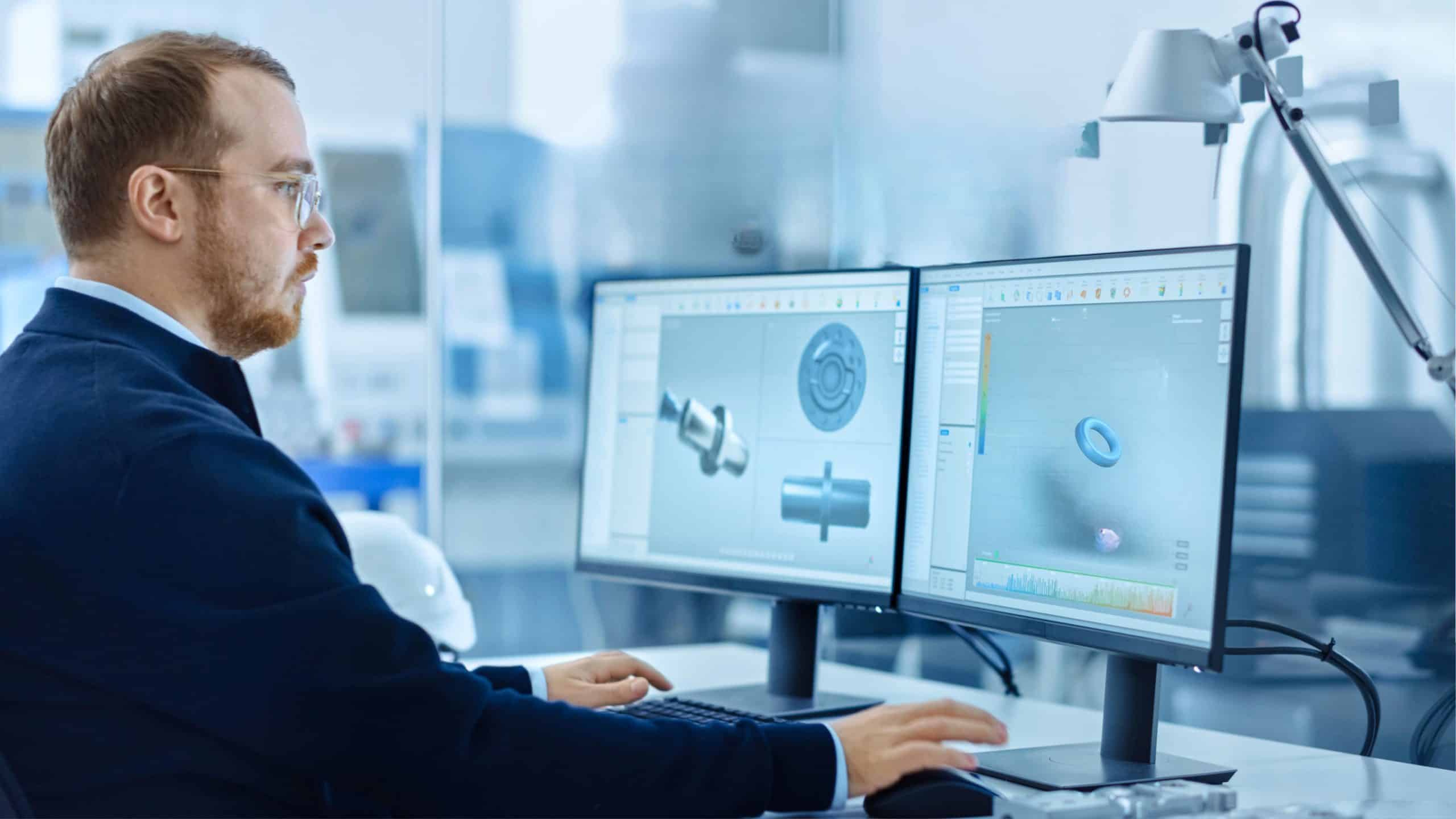

Simulating the behaviour of your parts, it's possible !

As part of your projects, ITC can offer behaviour simulation tests for your elastomer parts based on the constraints of your applications:

- Deformation

- Mechanical resistance to pressure

- Resistance to fluids (kerosene, solvents, chemicals, water, etc.)

- Temperature resistance

- Mountability

Our design office works closely with you to design tests tailored to each project and tailor-made formulations.

Contact us to accelerate your innovation:

Ensure the reliability of your Human-Machine Interfaces !

At ITC Elastomères, we design and manufacture advanced solutions for your human-machine interfaces:

-

Push buttons

-

Multi-material sensors

-

Overmolded membranes

Combining robustness, sealing, and conductivity, they ensure reliability and performance, even for miniature parts.

Feel free to contact our sales team for more information and to discover how we can help you enhance the reliability of your HMI solutions.

New mixers at ITC

𝐍𝐨𝐭𝐡𝐢𝐧𝐠 𝐜𝐚𝐧 𝐬𝐭𝐨𝐩 𝐈𝐓𝐂 𝐄𝐥𝐚𝐬𝐭𝐨𝐦𝐞̀𝐫𝐞𝐬 𝐢𝐧 𝐢𝐭𝐬 𝐭𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧!

After installing new presses, we now welcome brand new mixers

— and this is just the beginning…

- Even more high-performance formulations

- Enhanced silicone mixing capabilities

- Increased mixing capacity = boosted productivity

These investments mark another milestone in our growth, allowing us to meet our clients’ needs with even greater efficiency and technical excellence.

Back to business!

After a well-deserved summer break, the team is back, ready to take on your next challenges!

Don't hesitate to contact us to take care of all your elastomer technical parts projects. Have a great back-to-school season everyone!

Happy Summer Holidays to all!

ITC Élastomères is taking a summer break

Our facilities will be closed from August 2nd to 24th (inclusive).

We’ll be back on Monday, August 25th, recharged and ready to support all your technical elastomer part projects for the second half of the year!

And also, new features coming to ITC this fall...

We wish all our clients and partners a wonderful summer break

During the summer, let's protect our collaborators from the heat

During heatwaves like the ones we live nowadays, maintaining comfortable and stable production environments is a serious issue for industries working with hot equipment such as presses or vulcanization ovens.

At ITC Élastomères, our new Toury site was designed with this in mind:

A powerful climatisation system (VMC) ensures a controlled workshop temperature, even in extreme summer conditions.

Because innovation also means protecting employees and preserving process quality — no matter the weather.

ITC at the Heart of Space Design

Our Cap Is Headed to Space with Mumm Champagne!

Just days before its launch aboard the AX-4 mission, Mumm Cordon Rouge Stellar – a champagne designed to be enjoyed in zero gravity – was officially unveiled at the 2025 Paris Air Show, at the Latitude stand.

ITC is proud to have designed the cap for this exceptional bottle. The result of several months of collaboration with space design and engineering experts, this project – approved by NASA (National Aeronautics and Space Administration) – embodies ITC’s bold and shared vision of 100% French industrial, scientific, and innovative excellence.

A huge thank you to Octave de Gaulle and Charlie Zehnlé from Spade – the Space Design agency, for their trust; to Stanislas Maximin and Vincent Baudoin from Latitude for hosting us at their stand; and to all the partners present to celebrate this major milestone:

- Sébastien Barde and Caroline Laurent, Director of Orbital Systems and Applications at CNES

- Jean-François Clervoy (Official), astronaut and president of Novespace

- Etienne Cassuto from Pernod Ricard

- Benoit Moulas and Ludovic Daudois from Comat

- Vincent Buffenoir from Way4Space

Not to mention the Axiom Space team, hard at work in Houston for the upcoming launch to the International Space Station!

From left to right: Etienne Cassuto (Pernod Ricard), Vincent Buffenoir (Way4Space), Charlie Zehnlé (Spade), Christophe Beauvais (ITC), Jean-François Clervoy (Novespace), Vincent Baudoin (Latitude), Octave de Gaulle (Spade), Ludovic Daudois (COMAT)

Welcome to electric vehicles at our site in Toury!

As part of our commitment to sustainabillity, we are proud to have installed electric vehicle charging stations on our site.

This initiative is fully in line with our commitment to:

- Reducing our carbon footprint

- Encouraging electric mobility among our employees and visitor

At ITC Elastomers, innovation also means thinking about the environment.

Happy Labour Day!

On this Labour Day, let’s take a moment to recharge, reflect, and enjoy some well-earned rest — whether it’s with family, friends, or simply a bit of quiet time.

A big thank you to everyone who contributes each day to making our work meaningful and impactful.

Focus on safety and well-being at work

With our new factory, we are taking another step towards a healthier, safer, and more pleasant work environment:

- Brighter spaces

- A high-performance air handling unit for regulated temperature and renewed air,

- Guardrails installed in high-rise areas

- And, of course, a wide range of Personal Protective Equipment (PPE) available to our operators.

Because a safe work environment is the foundation for everyone to perform their jobs in the best possible conditions.

At ITC Elastomers, workplace safety and well-being are not optional.